Transform your processes and supply chain operations with Dynamics 365 Supply Chain Management. And use predictive insights from AI and The Internet of Things (IoT) in planning, production, inventory, warehousing, and transportation management to dramatically improve operational efficiency, product quality, and profitability.

Provide the most suitable process through intelligent manufacturing

- Create a connected factory: Drive smarter processes and operations by using IoT, AI, machine learning, and mixed reality to optimize people, processes, and equipment.

- Simplify resource management : across any workload with an intelligent solution that helps you track and manage your resources — from your workforce to machines and tools.

- Create best-fit manufacturing processes: discrete, lean, project, process, and mixed-mode — to address all your needs with a single solution.

- Deliver mixed-mode manufacturing: support all your manufacturing strategies, including make to stock, make to order, configure to order, and engineer to order.

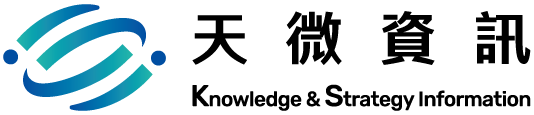

- Perform production planning in real time: reducing lead-time for new demands and supply — with Planning Optimization Preview.

- Accelerate product delivery: by automating the flow of information and materials through your resources and locations.

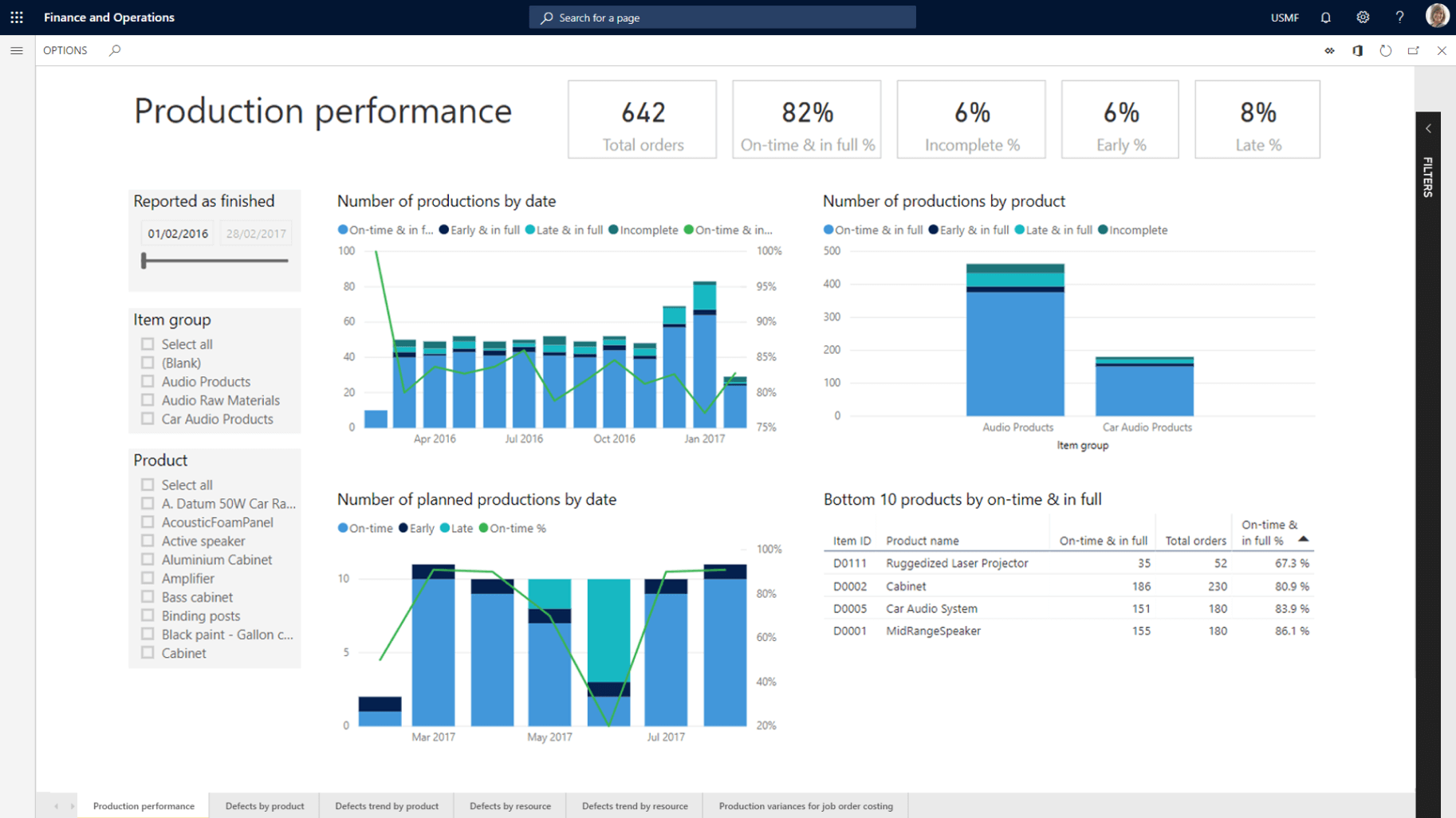

Optimize production performance with IoT Intelligence Preview

- Make proactive, actionable decisions with a real-time view of your entire production and stock. Proactively manage shop floor and equipment operations to improve uptime, throughput, and quality.

- Drive efficiency across your assets, processes, and workforce by using AI, machine learning, and mixed reality to predict and proactively resolve issues.

- Perform predictive maintenance before disruptive failure occurs to avoid costly downtime of business-critical equipment.

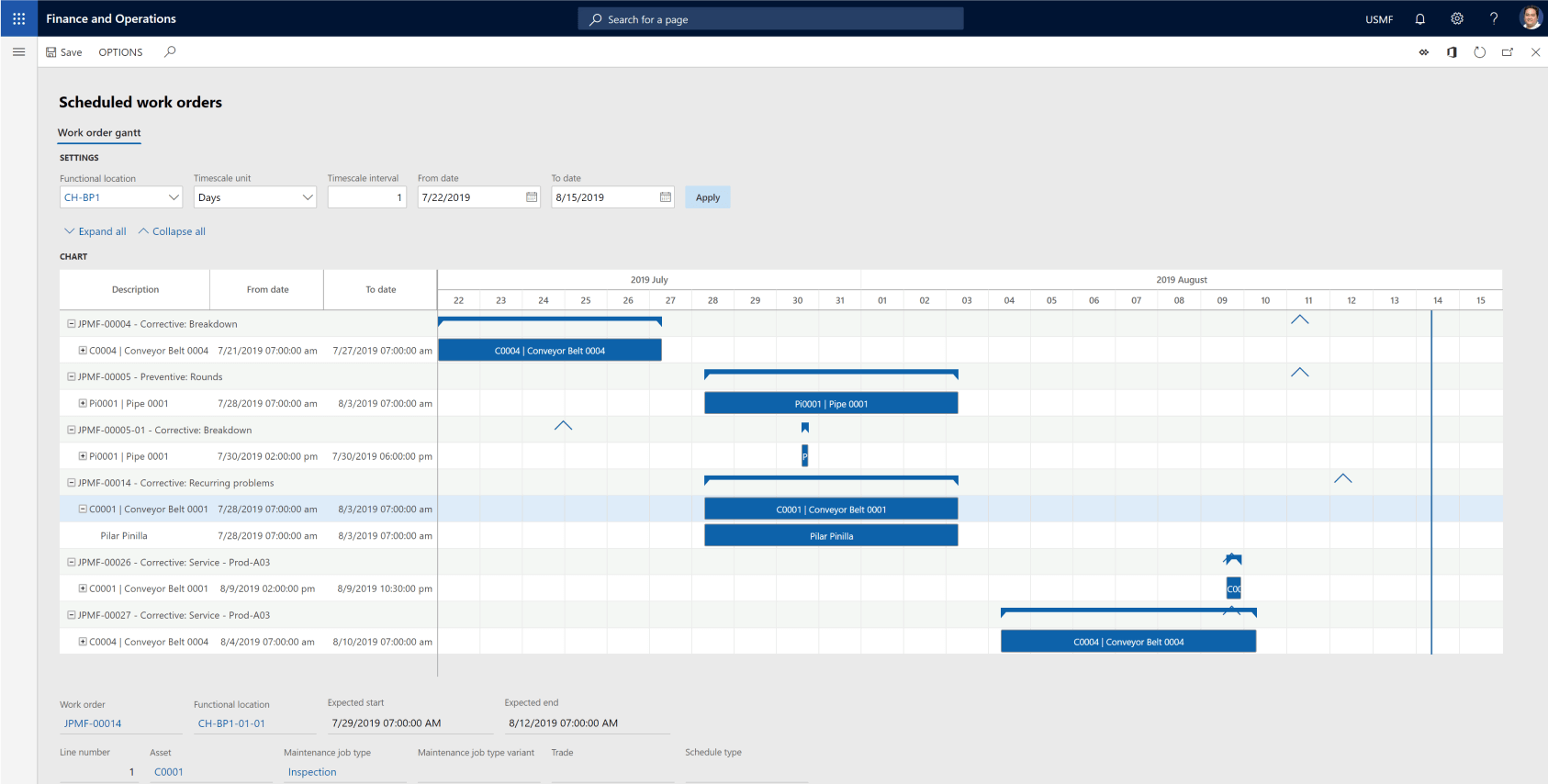

Maximize the life of your assets with Asset Management

Asset Management is an advanced module for managing assets and maintenance, with the following characteristics:

- Better maintain your assets from acquisition to retirement by streamlining tracking and monitoring KPIs to improve the overall equipment effectiveness (OEE) of your mission-critical assets.

- More effectively plan and predict maintenance to maximize the longevity and performance of high-value assets while reducing costs and production downtime.

- Support various types of maintenance — predictive, corrective, condition, and preventative — with a single solution.

- Match different channel sales and cost data to help determine the best and most effective marketing practices.

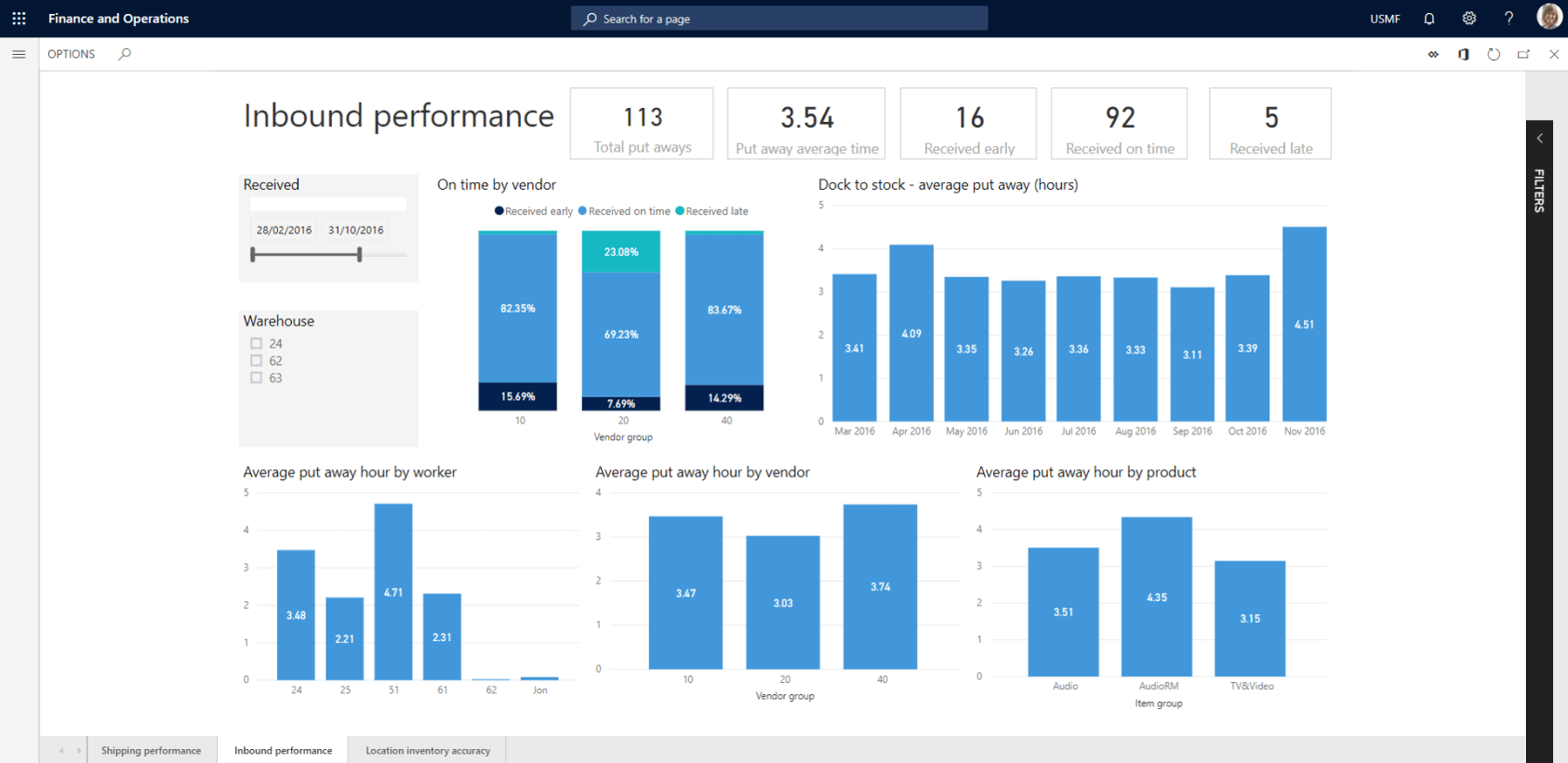

Modernize warehouse management

- Gain complete end-to-end visibility of your warehouse operations and inventory to effectively manage capacity and consumption of your raw materials and movement of finished goods in real time.

- Automate and scale your warehouse management to optimize use of space—from simple stock rooms to distribution centers. Effectively manage materials and finished goods with configurable machine learning-based guidance.

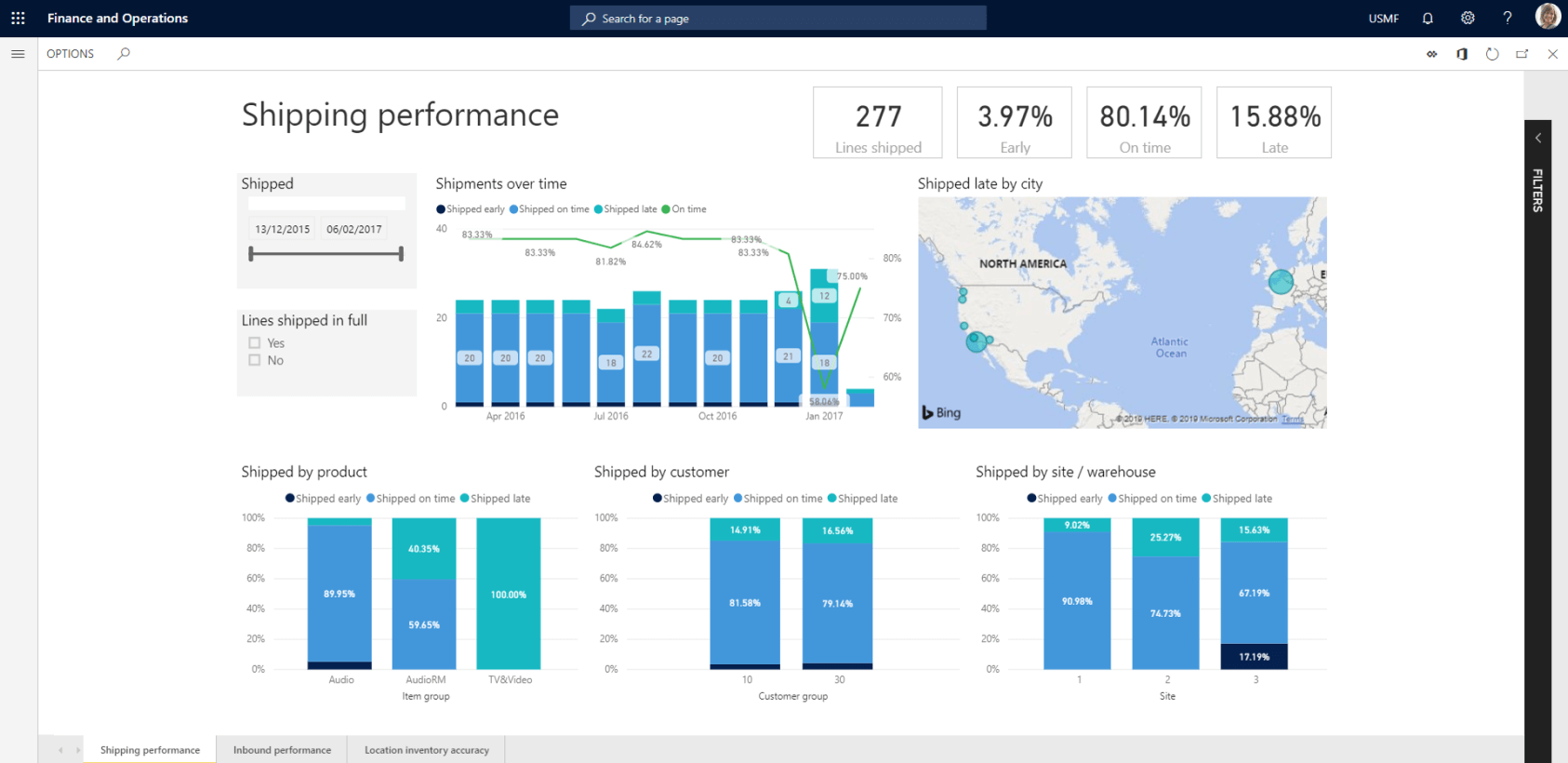

- Get real-time intelligence about the health of your warehouse with out-of-the-box Power BI warehousing analytics that gives you full visibility of your inventory and receiving, picking, and shipping operations. Easily create no-code customized heatmaps of your warehouse processes.

- Improve productivity with a mobile app that can be tailored for employees and warehouses to simplify the performance of daily tasks.

Automate and streamline your supply chain

- Get a complete view of your supply chain across geographies and time zones when you integrate sales and purchasing with logistics, inventory, production, warehouse, and transportation management.

- Streamline your procurement processes by using a single application for procure-to-pay to manage contracts, onboard vendors, monitor on-time delivery performance, and collaborate with external vendors.

- Improve customer orders and delivery with more accurate delivery date estimates that take into account material availability and capacity constraints across companies, sites, and warehouses.

- Optimize fulfillment and reduce costs by synchronizing logistics across sites, warehouses, and transportation modes.

- Accelerate product delivery by automating the flow of information and materials through your resources and locations.

- Increase quality and customer satisfaction with integrated quality control capabilities, and quickly identify and resolve issues through real-time, predictive insights.