Suitable industries: central kitchen, group catering company, catering manufacturing industry, food manufacturing industry

Industry Demand:

- It is necessary to accurately predict the amount of raw materials consumed and reduce waste

- To meet the different needs of bento boxes, company line number group meal dishes, etc., it is necessary to establish a variety of dish cycles

- There are many types of ingredients, many product numbers, and the raw materials are also prone to change due to menu adjustments or price fluctuations of ingredients

- The production cycle is short, the material turnover speed is fast, and the amortization of the cost of pre-issued materials is complex, and the inventory is not easy

- Measures for the Administration of Traceability System for Food and Related Products in Accordance with the Food Safety Law

- The front-end production, invoicing system and back-end financial system are often independent, which requires a lot of manpower and time to enter information

Solution:

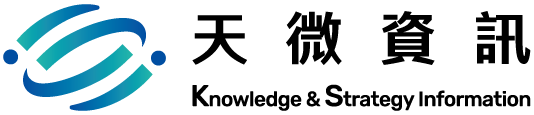

- Food Forecasting and Material Procurement Management

According to the forecast data and order content, it can be converted into a purchase BOM, even if the quantity increases or decreases after the order is established, it can also generate a BOM with different effective dates, which can accurately estimate the quantity of ingredients, facilitate procurement management and statistics, and reduce waste.

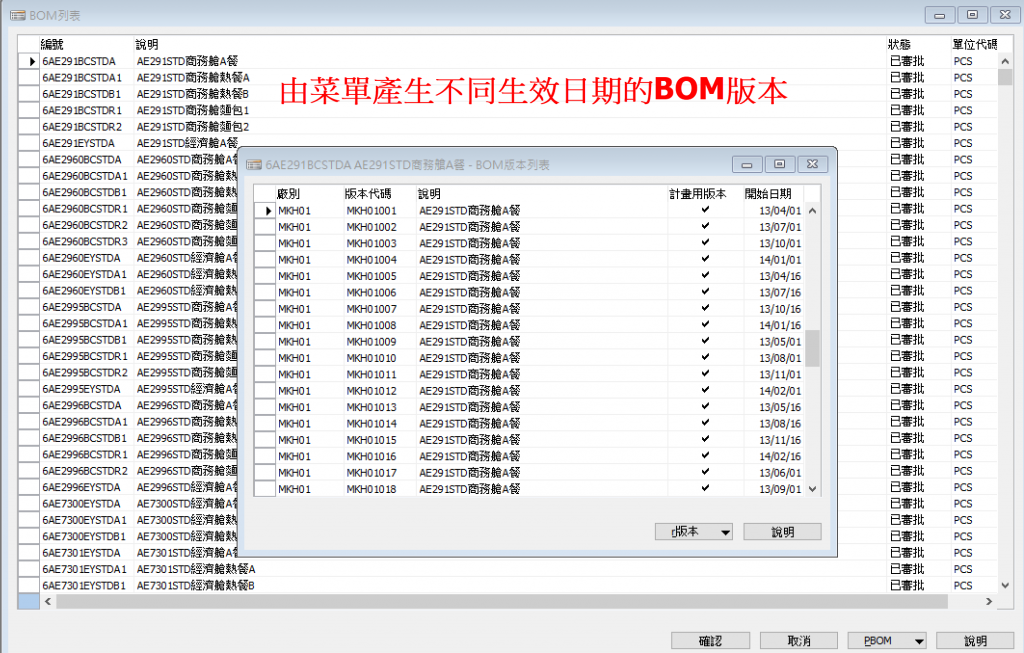

- Menu design management

You can create different menus according to the type of bento and set meal, and you can make different cycle configurations according to the month and day, and you can also import the menu designed in advance with Excel.

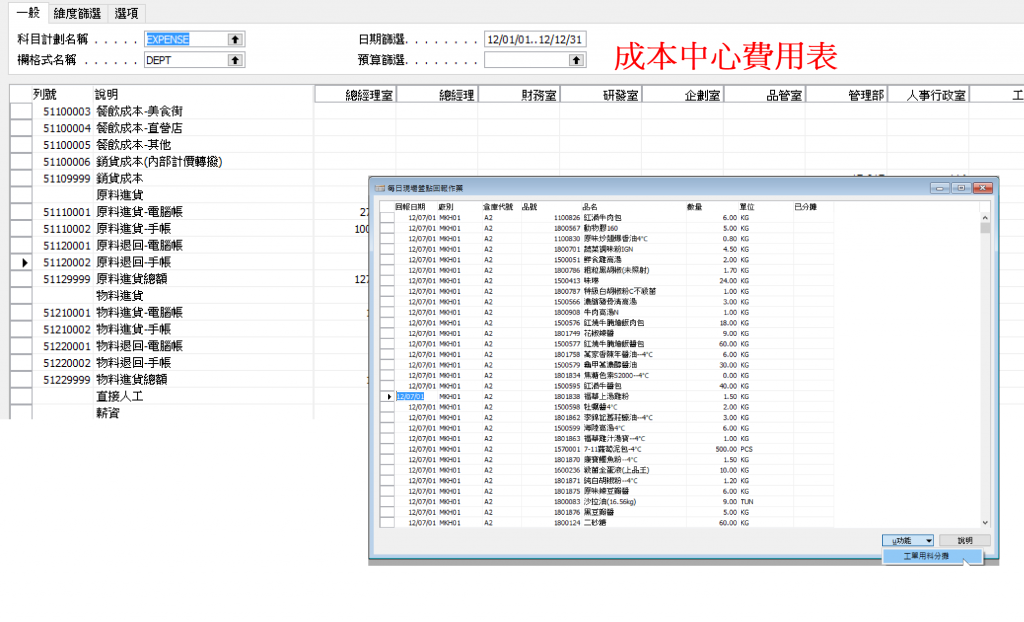

- Production cost allocation and management

The cost of daily meals can be known in real time, which is different from relying on manual statistics of daily meal costs in the past, and now the cost of meals can be quickly calculated and amortized according to the daily inventory quantity, and the profit and loss statement can be generated according to the cost profit center of the factory area and the meal type for the management to refer to, so as to respond to the fluctuation of vegetable prices and various raw material costs in a timely manner.

- Food traceability system

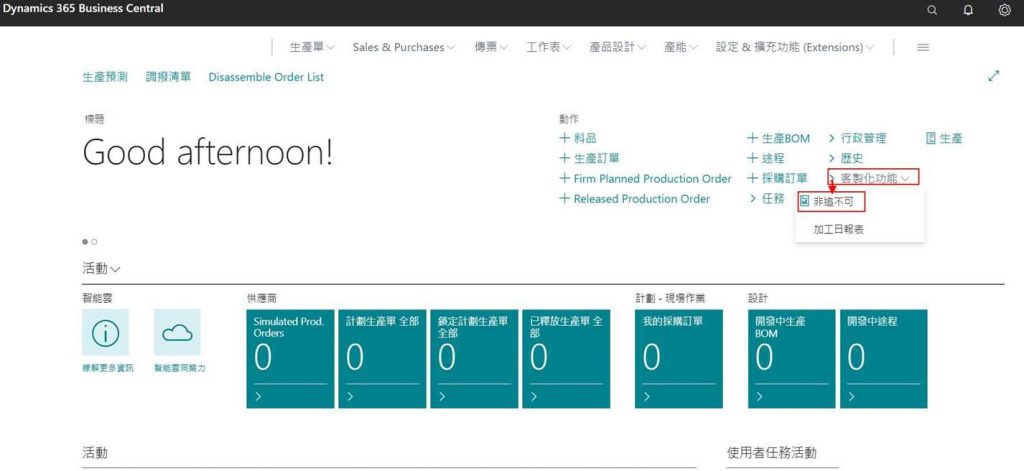

According to the “Measures for the Administration of Food and Related Product Traceability System”, food traders should keep complete food traceability certificates, documents and other records in the form of “written or electronic documents” for at least 5 years. Through the establishment of a food traceability system, raw material information, product information, product flow and other information are regularly uploaded to the “non-traceable” system of the Food and Drug Administration, and complete traceability information can be quickly provided through Microsoft Dynamics 365 ERP for the competent authority and customer audit.

- Integrate manufacturing and back-end financial systems

Connect front-end manufacturing, purchase, sales, inventory, and back-end financial processes with Microsoft Dynamics to reduce manual data entry time and labor costs, reduce error rates, and speed up checkout.