Suitable industry: machine tool industry/equipment industry/machinery industry

Industry Demand:

- There are many components and items, and it is not easy to manage

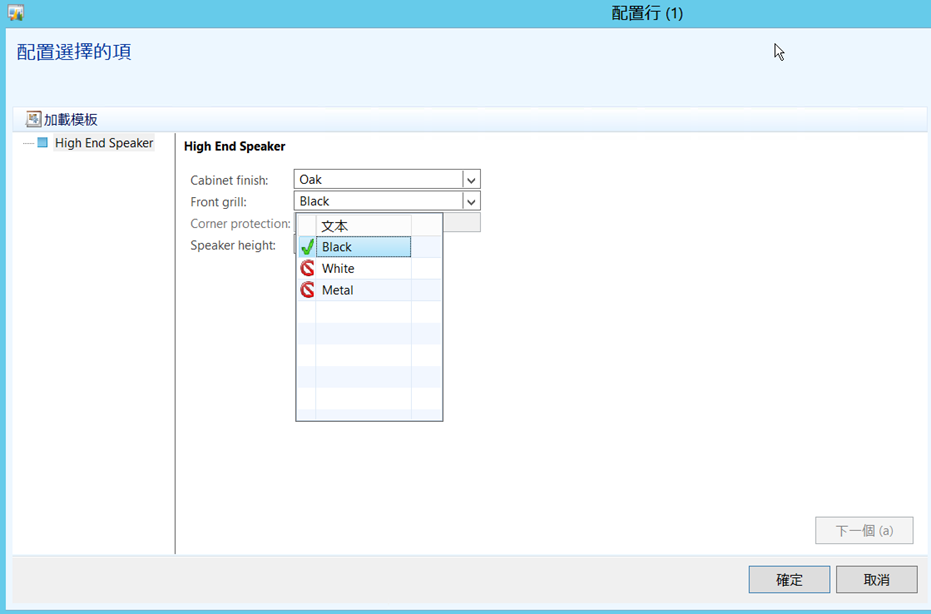

- Customized demand must be confirmed by the R&D unit, and the quotation takes time

- It is necessary to cooperate with the customer’s delivery date and often insert orders, which makes it difficult to arrange production plans, and production line planning and capacity control are complicated

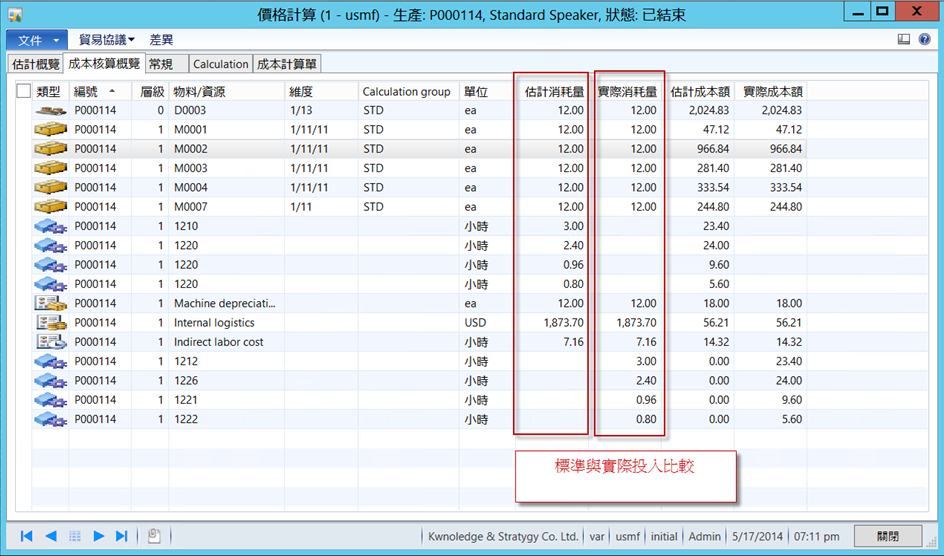

- Product cost settlement statistics are time-consuming and labor-intensive, and financial personnel are busy and difficult to provide the actual cost of products in real time

- In response to the demand of the order, it is necessary to temporarily adjust the production route

- Carry out project management according to customer orders to control the status of R&D schedule, procurement plan, assembly progress, etc

Solution:

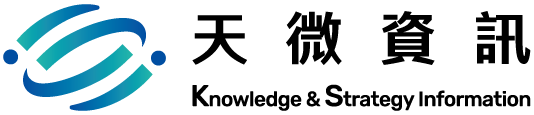

- The main file of the material can display the product drawing file, and the CAD file can also be called out to increase the identification of the components. It can also query the existing inventory and production billing, simplifying the complexity of management.

- For standard products and standard optional products, the detailed configuration can be selected according to the pre-set rules through the BOM configuration, and the BOM list will be automatically generated by the system, saving quotation time

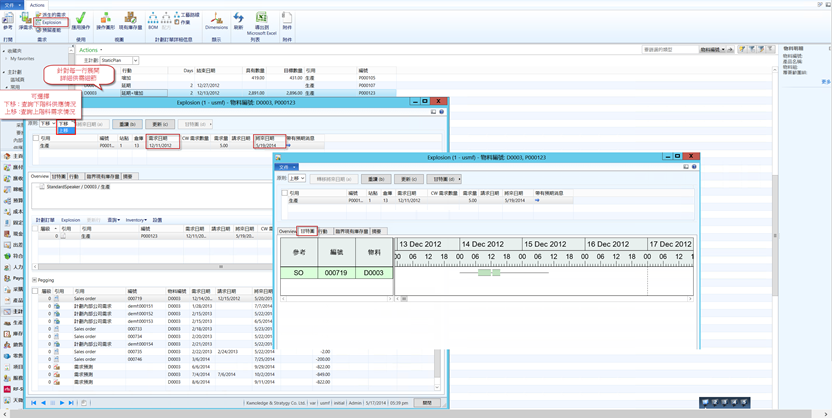

- The time required for the production plan can be referred from the customer’s delivery date, and the production plan can be displayed in a graphical Gantt chart. Microsoft Dynamics 365 Finance and Operations has built-in Advanced Planning and Scheduling (APS) capabilities, which can arrange limited capacity scheduling and material calculation according to the system, and can also confirm capacity retention and capacity load status.

-

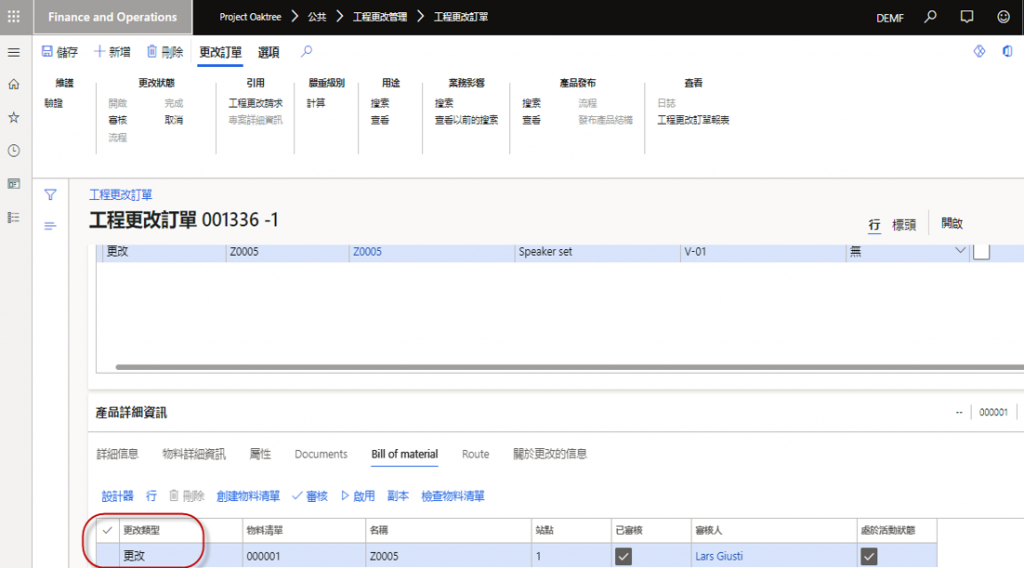

Engineering Change Management

In the face of customer needs, material shortages, design changes, etc., resulting in frequent engineering changes. The system provides an engineering change management mechanism to achieve product version control. The items that can be managed include the bill of materials and the changes in the itinerary, and can be notified to the relevant departments through the workflow and reviewed.

- The production cost can be managed through the system, as well as the difference between the actual cost and the standard cost, without the need for financial personnel to manually calculate by themselves